-

REDSUN R37 Series helical speed reducers gearbox with 0.18~3KW AC motor

1. The structure scheme, appearance diagram and other attached diagrams in sample are examples,there is no strict proportion requirement. If you need exact dimension of certain types, please contactour sales dept.. (The unmarked dimension units are mm).2. Gear unit has been tested before delivered, users should add lubrication oil before running.3. We can only refer to the marked oil in the mannul. Actual oil filling level should be the same withthe mark on oil immersion lens.4. Lubrication oil viscosity should be selected according to working conditions and ambienttemperature.5. To prevent accidents, all the rotation parts should be added with protective covers according tosafety regulation of the nation and region.6. The solid shaft input structure gear unit is not equipped with any motor.7. Motors of Y series are supplied with protection grade of IP54 unless otherwise specified.8. Unless otherwise specified, you will receive the terminal box at 0°.

1. The structure scheme, appearance diagram and other attached diagrams in sample are examples,there is no strict proportion requirement. If you need exact dimension of certain types, please contactour sales dept.. (The unmarked dimension units are mm).2. Gear unit has been tested before delivered, users should add lubrication oil before running.3. We can only refer to the marked oil in the mannul. Actual oil filling level should be the same withthe mark on oil immersion lens.4. Lubrication oil viscosity should be selected according to working conditions and ambienttemperature.5. To prevent accidents, all the rotation parts should be added with protective covers according tosafety regulation of the nation and region.6. The solid shaft input structure gear unit is not equipped with any motor.7. Motors of Y series are supplied with protection grade of IP54 unless otherwise specified.8. Unless otherwise specified, you will receive the terminal box at 0°.

Q: Are you trading company or manufacturer ?

A: We are factory.Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock.Q: Can we buy 1 pc of each item for quality testing?

A: Yes, we are glad to accept trial order for quality testing.Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance, balance before shippment.

If you have other question, freely to contact us,please. -

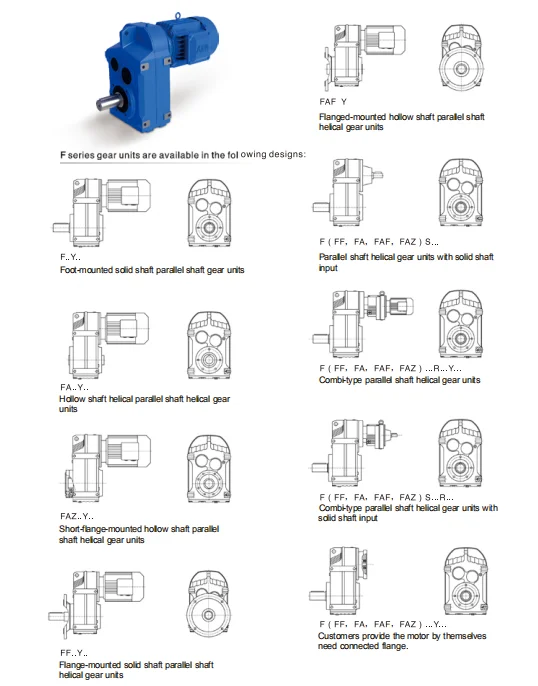

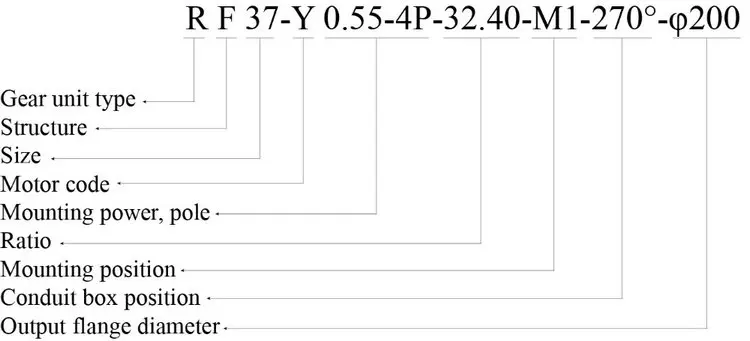

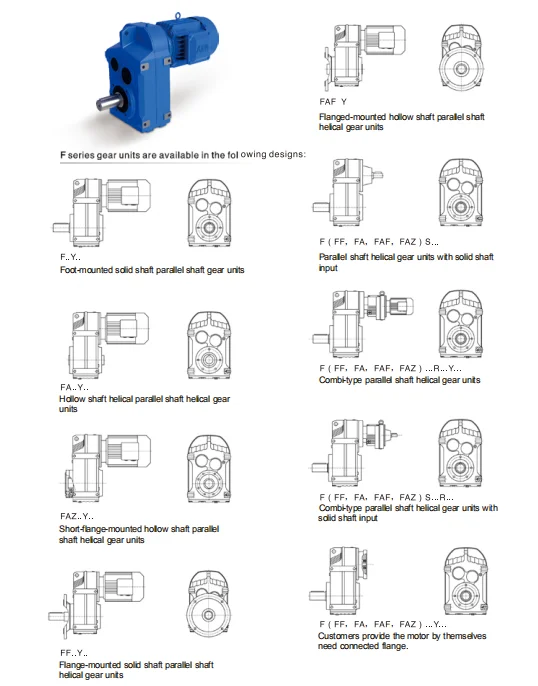

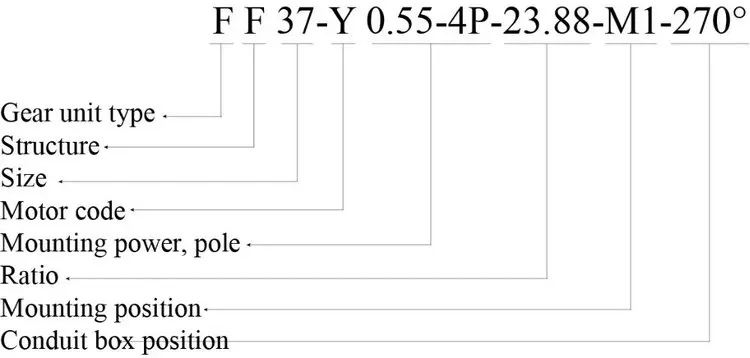

F series foot mounted solid or hollow parallel shaft helical gear box with electric motor

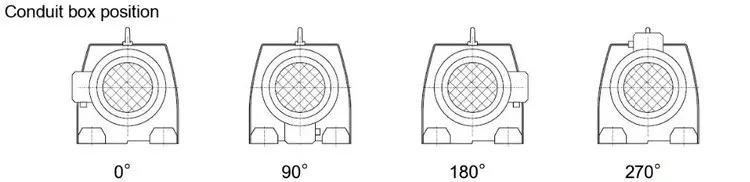

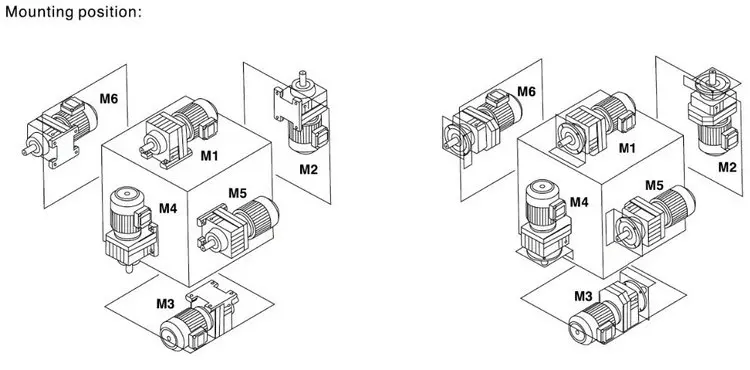

1. The structure scheme, appearance diagram and other attached diagrams in sample are examples, thereis no strict proportion requirement. If you need exact dimension of certain types, please contact our sales dept..(The unmarked dimension units are mm).2. Gear unit has been tested before delivered, users should add lubrication oil before running.3. We can only refer to the marked oil in the mannul. Actual oil filling level should be the same with the markon oil immersion lens.4. Lubrication oil viscosity should be selected according to working conditions and ambient temperature.5. To prevent accidents, all the rotation parts should be added with protective covers according to safetyregulation of the nation and region.6. The solid shaft input structure gear unit is not equipped with any motor.7. Motors of Y series are supplied with protection grade of IP54 unless otherwise specified.8. Unless otherwise specified, you will receive the terminal box at 0°.

1. The structure scheme, appearance diagram and other attached diagrams in sample are examples, thereis no strict proportion requirement. If you need exact dimension of certain types, please contact our sales dept..(The unmarked dimension units are mm).2. Gear unit has been tested before delivered, users should add lubrication oil before running.3. We can only refer to the marked oil in the mannul. Actual oil filling level should be the same with the markon oil immersion lens.4. Lubrication oil viscosity should be selected according to working conditions and ambient temperature.5. To prevent accidents, all the rotation parts should be added with protective covers according to safetyregulation of the nation and region.6. The solid shaft input structure gear unit is not equipped with any motor.7. Motors of Y series are supplied with protection grade of IP54 unless otherwise specified.8. Unless otherwise specified, you will receive the terminal box at 0°.

Q: Are you trading company or manufacturer ?

Q: Are you trading company or manufacturer ?A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock.Q: Can we buy 1 pc of each item for quality testing?

A: Yes, we are glad to accept trial order for quality testing.Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance, balance before shippment.

If you have other question, freely to contact us,please. -

P series planetary speed reducer wind turbine speed increase planetary gearbox transmission gear box mixer planetary

Ratio:up to 4200

Mounting Position:Foot Mounted,flange Mounted

Gear material:20CrMnTi

Housing Material:HT200

Heat treatment:Normalizing,carburizing,high-frequency heating,quenching

Warranty:12 Months

Bearing:NSK,HRB,ZWZ,C&U,etc

Certificate:ISO9001:2015,ISO14001:2015

Color:Blue RAL5010,grey RAL7040/7031

Certification:CE,ISO9001:2015

Applicable Industries:Manufacturing Plant

Applicable Industries:Machinery Repair Shops

Applicable Industries:Food & Beverage Factory

Applicable Industries:Farms

Applicable Industries:Construction works

Applicable Industries:Energy & Mining

Customized support:OEM

Customized support:ODM

Customized support:OBM

Gearing Arrangement:Helical

Place of Origin:CN;ZHE

Warranty:1 year

Weight (KG):50

Brand Name:REDSUN

Output Torque:up to 200000Nm

Input Speed:up to 2000rpm

Output Speed:up to 80rpm -

P series Helical Bevel cycloidal gear planetary speed reducer gearbox for mill

Ratio:up to 4200

Mounting Position:Foot Mounted,flange Mounted

Gear material:20CrMnTi

Housing Material:HT200

Heat treatment:Normalizing,carburizing,high-frequency heating,quenching

Warranty:12 Months

Bearing:NSK,HRB,ZWZ,C&U,etc

Certificate:ISO9001:2015,ISO14001:2015

Color:Blue RAL5010,grey RAL7040/7031

Certification:CE,ISO9001:2015

Applicable Industries:Manufacturing Plant

Applicable Industries:Machinery Repair Shops

Applicable Industries:Food & Beverage Factory

Applicable Industries:Farms

Applicable Industries:Construction works

Applicable Industries:Energy & Mining

Customized support:OEM

Customized support:ODM

Customized support:OBM

Gearing Arrangement:Helical

Place of Origin:CN;ZHE

Warranty:1 year

Weight (KG):50

Brand Name:REDSUN

Output Torque:up to 200000Nm

Input Speed:up to 2000rpm

Output Speed:up to 80rpm -

P series planetary gearbox,high torque planetary reducer,planetary gear

Ratio:up to 4200

Mounting Position:Foot Mounted,flange Mounted

Gear material:20CrMnTi

Housing Material:HT200

Heat treatment:Normalizing,carburizing,high-frequency heating,quenching

Warranty:12 Months

Bearing:NSK,HRB,ZWZ,C&U,etc

Certificate:ISO9001:2015,ISO14001:2015

Color:Blue RAL5010,grey RAL7040/7031

Certification:CE,ISO9001:2015

Applicable Industries:Manufacturing Plant

Applicable Industries:Machinery Repair Shops

Applicable Industries:Food & Beverage Factory

Applicable Industries:Farms

Applicable Industries:Construction works

Applicable Industries:Energy & Mining

Customized support:OEM

Customized support:ODM

Customized support:OBM

Gearing Arrangement:Helical

Place of Origin:CN;ZHE

Warranty:1 year

Weight (KG):50

Brand Name:REDSUN

Output Torque:up to 200000Nm

Input Speed:up to 2000rpm

Output Speed:up to 80rpm -

R rigid tooth flank speed reducer High efficiency helical gear reducer helical reducer Helical gearbox

Gears:Helical Gears Transmission Gear Box

Ratio:1.3~289.74

Application:Power Transmission

Product name:Gearbox

Color:RAL5010(blue)

Warranty:12 Months

Mounting Position:Horizontal (foot Mounted)

Packing:Wooden Box

Customization:Acceptable

Housing Material:Iron Casting

Applicable Industries:Building Material Shops

Applicable Industries:Manufacturing Plant

Applicable Industries:Machinery Repair Shops

Applicable Industries:Food & Beverage Factory

Applicable Industries:Farms

Applicable Industries:Construction works

Applicable Industries:Energy & Mining

Customized support:OEM

Customized support:ODM

Customized support:OBM

Gearing Arrangement:Helical

Place of Origin:CN;ZHE

Warranty:1 year

Weight (KG):50

Brand Name:REDSUN

Output Torque:up to 20000Nm

Input Speed:up to 2000rpm

Output Speed:up to 1500rpm -

R series industry transmission helical speed gearbox worm geard motor 7.5kw speed reducer/R37R47R57R67R77R87R97R107 gear MOTOR

Gears:Helical Gears Transmission Gear Box

Ratio:1.3~289.74

Application:Power Transmission

Product name:Gearbox

Color:RAL5010(blue)

Warranty:12 Months

Mounting Position:Horizontal (foot Mounted)

Packing:Wooden Box

Customization:Acceptable

Housing Material:Iron Casting

Applicable Industries:Building Material Shops

Applicable Industries:Manufacturing Plant

Applicable Industries:Machinery Repair Shops

Applicable Industries:Food & Beverage Factory

Applicable Industries:Farms

Applicable Industries:Construction works

Applicable Industries:Energy & Mining

Customized support:OEM

Customized support:ODM

Customized support:OBM

Gearing Arrangement:Helical

Place of Origin:CN;ZHE

Warranty:1 year

Weight (KG):50

Brand Name:REDSUN

Output Torque:up to 20000Nm

Input Speed:up to 2000rpm

Output Speed:up to 1500rpm -

China manufacturer XW series planetary cycloidal pinwheel gear speed reducer gearbox for sale

Applicable Industries:Building Material Shops

Applicable Industries:Machinery Repair Shops

Applicable Industries:Construction works

Applicable Industries:Energy & Mining

Applicable Industries:Other

Customized support:OEM

Customized support:ODM

Customized support:OBM

Gearing Arrangement:Cycloidal

Place of Origin:CN

Weight (KG):45

Output Torque:1.8-2430N.M

Input Speed:750-1500rpm

Output Speed:14-280rpm

Brand Name:Redsun -

Helical Bevel cycloidal gear planetary speed reducer electric motor reductor gearbox

Applicable Industries:Building Material Shops

Applicable Industries:Machinery Repair Shops

Applicable Industries:Construction works

Applicable Industries:Energy & Mining

Applicable Industries:Other

Customized support:OEM

Customized support:ODM

Customized support:OBM

Gearing Arrangement:Cycloidal

Place of Origin:CN

Weight (KG):45

Output Torque:1.8-2430N.M

Input Speed:750-1500rpm

Output Speed:14-280rpm

Brand Name:Redsun -

REDSUN high quality ZLYJ series single-screw gearbox for plastic extruder in stock for sell

Ratio:up to 20

Certificates:CE,ISO9001

Warranty:1 Year

Heat treatment:High Frequency Quenching

Keyword:ZLYJ extruder

Input Form:Thrust structure

Certification:CE,ISO9001:2015

Applicable Industries:Building Material Shops

Applicable Industries:Manufacturing Plant

Applicable Industries:Machinery Repair Shops

Applicable Industries:Food & Beverage Factory

Applicable Industries:Farms

Applicable Industries:Construction works

Applicable Industries:Energy & Mining

Customized support:OEM

Customized support:ODM

Customized support:OBM

Gearing Arrangement:Helical

Place of Origin:CN;ZHE

Warranty:1 year

Weight (KG):50

Brand Name:REDSUN

Output Torque:up to 36000N.m

Input Speed:up to 2000rpm

Output Speed:up to 240rpm -

Hard Gear Surface Helical Gearbox Speed ZLYJ 200/250/280/315 Gearbox Reducer

Ratio:up to 20

Certificates:CE,ISO9001

Warranty:1 Year

Heat treatment:High Frequency Quenching

Keyword:ZLYJ extruder

Input Form:Thrust structure

Certification:CE,ISO9001:2015

Applicable Industries:Building Material Shops

Applicable Industries:Manufacturing Plant

Applicable Industries:Machinery Repair Shops

Applicable Industries:Food & Beverage Factory

Applicable Industries:Farms

Applicable Industries:Construction works

Applicable Industries:Energy & Mining

Customized support:OEM

Customized support:ODM

Customized support:OBM

Gearing Arrangement:Helical

Place of Origin:CN;ZHE

Warranty:1 year

Weight (KG):50

Brand Name:REDSUN

Output Torque:up to 36000N.m

Input Speed:up to 2000rpm

Output Speed:up to 240rpm -

B series High quality Right Angle Parallel Shaft Unique speed reducer HB helical gearbox / gear box

Ratio:up to 400

Mounting Position:Foot Mounted,flange Mounted

Gear material:20CrMnTi Steel

Housing Material:Cast iron

Heat treatment:Normalizing,carburizing,high-frequency heating,quenching

Warranty:12 Months

Bearing:NSK,HRB,ZWZ,C&U,etc

Certificate:ISO9001:2015,ISO14001:2015

Color:Grey RAL7031/7040,blue RAL5010

Certification:CE,ISO9001:2015

Applicable Industries:Manufacturing Plant

Applicable Industries:Machinery Repair Shops

Applicable Industries:Food & Beverage Factory

Applicable Industries:Construction works

Applicable Industries:Energy & Mining

Customized support:OEM

Customized support:ODM

Customized support:OBM

Gearing Arrangement:Helical

Place of Origin:CN;ZHE

Warranty:1 year

Weight (KG):300

Output Torque:up to 1000KN.m

Input Speed:up to 2000rpm

Output Speed:up to 400rpm

Brand Name:REDSUN